When it comes to reliable and efficient heating and melting equipment, Seba Developments stands as your trusted partner. With over 40 years of manufacturing expertise, we pride ourselves on delivering high-quality solutions tailored to your specific needs.

Our Comprehensive Range of Heating and Melting Equipment

Whether you’re an industrial professional or a hobbyist, we offer a diverse selection of equipment to meet your requirements:

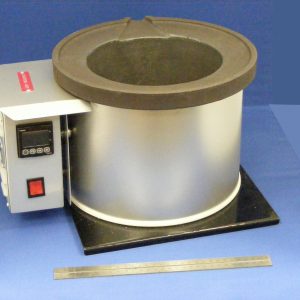

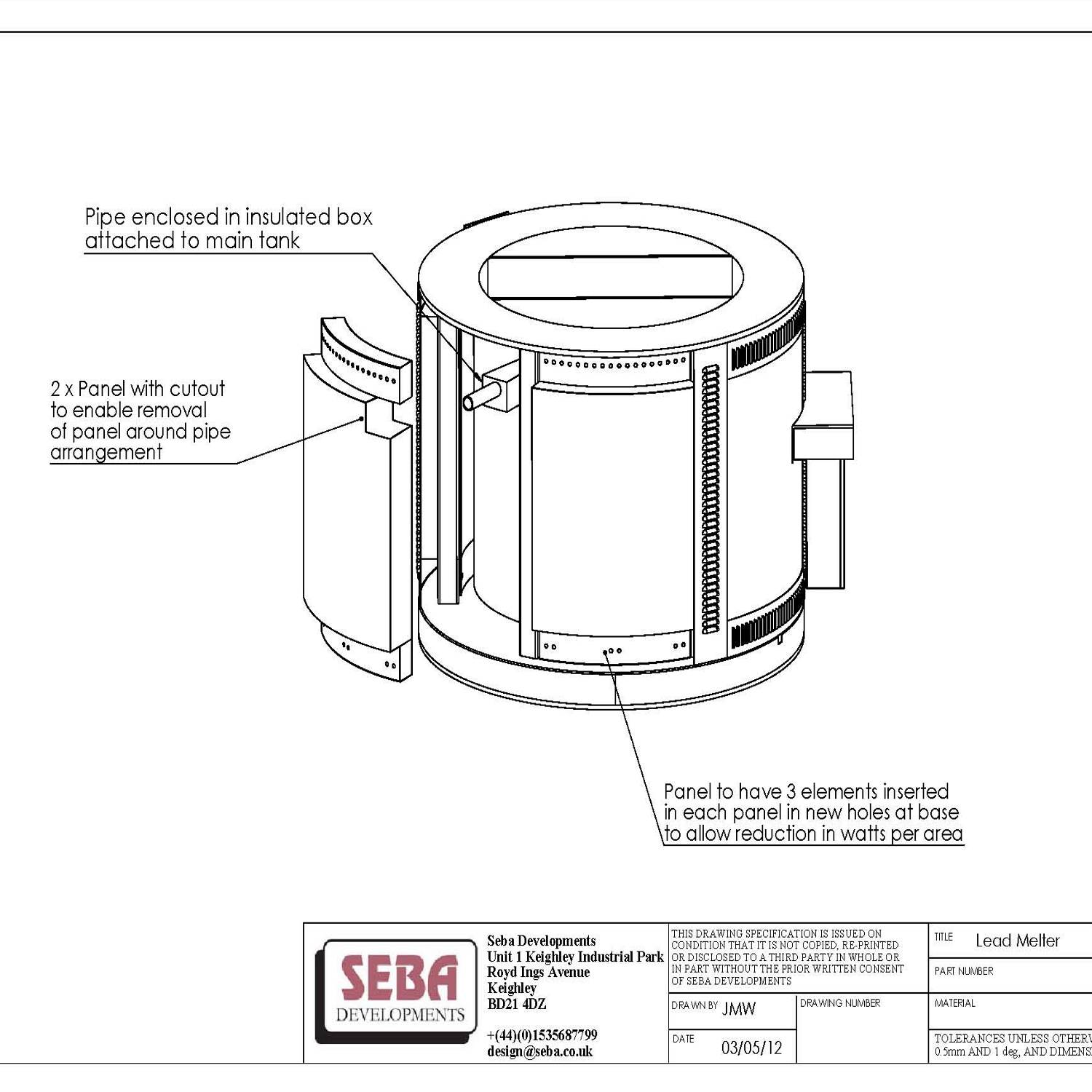

– Wax and Metal Melting Equipment:

Achieve precision in your metalworking and crafting projects with our advanced wax and metal melting solutions. From small-scale hobbyist needs to large-scale industrial applications, we have the right equipment for you.

– Centrifugal Casting Tools:

Experience the art of centrifugal casting with our top-of-the-line tools and equipment. Our centrifugal casting solutions are designed to deliver consistent results, ensuring your projects are a success every time.

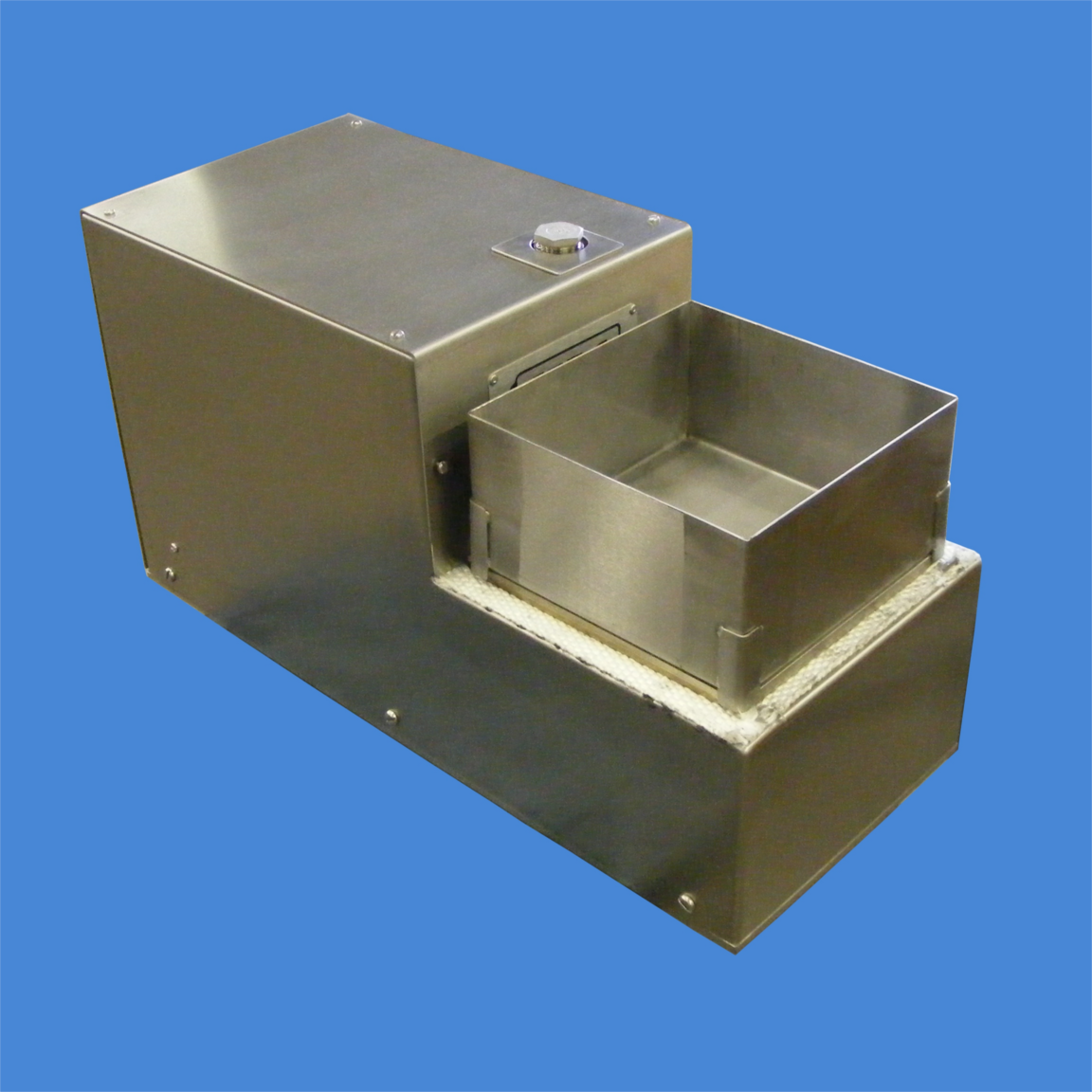

– Industrial Ovens:

For industrial processes that demand precise temperature control and reliability, our industrial ovens are the answer. They are built to withstand the rigors of industrial use while maintaining the highest standards of quality.

Check out our full catalogue below

Customized Solutions Tailored to You

At Seba Developments, we understand that every project has unique requirements. That’s why our friendly technical sales team is here to assist you in finding the perfect equipment. And if you can’t find exactly what you need in our catalog, don’t hesitate to reach out to us. We specialize in crafting bespoke equipment to meet your specific needs.

With Seba Developments as your partner, you can trust in our experience, commitment to quality, and dedication to providing top-notch heating and melting equipment. Contact us today, and let us help you achieve your project’s goals.